Understanding Aggregate Exposure in Polished Concrete

Polished concrete floors are an excellent choice when it comes to durability and maintenance. With a range of final appearances available, concrete grinders can be used to create different levels of aggregate exposure depending on the desired look.

Aggregate exposure

Aggregate exposure refers to the different cut depths and the amount and size of the stone exposed in the final finish. It ranges from cream, which is the finest aggregate, to large aggregate. The cuts used will depend on the project and the desired outcome.

Large aggregate exposure can provide a very attractive finish similar to some terrazzo applications. It requires aggressive grinding which can increase the cost of the project and may result in small pits or divots that need to be filled. It is important to note that the degree of sand and aggregate exposure, as well as small pits and divots, can have a significant impact on the gloss, durability, and cleanability of the concrete floor.

On the other end of the spectrum, cream exposure is the least aggressive option. It does not remove existing blemishes or imperfections in the concrete, and since it is a less invasive process and it does not require as much grinding thus the least expensive exposure level

In between these two options, class B, offers a middle price point. This is the most common level and is often referred to as salt and pepper exposure. This depth of cut provides enough removal to minimize finishing blemishes with a smaller cost due to the less aggressive grinding processes. This is our default option for most floors with a balance between cost and the aesthetics of the concrete surface.

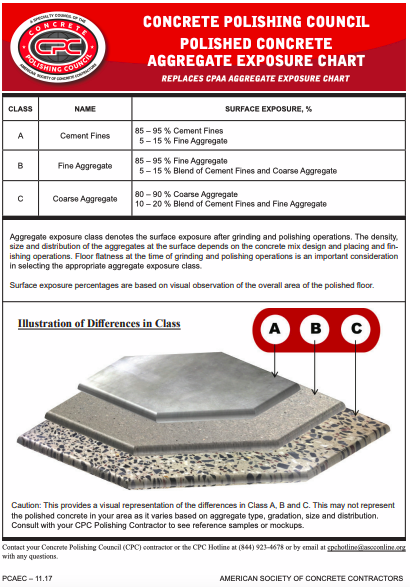

CPC Polished Concrete Aggregate Chart

It is based on the amount of grinding that has been done and the type of aggregate used. It helps to determine the amount of aggregate exposure that is desired in a polished concrete floor. It’s divided into three sections: light, medium, and heavy exposure. Each of them is further divided into percentages that indicate the amount of aggregate that will be exposed. For example, light exposure will have a range of 0-25%, medium exposure will have a range of 25-50%, and heavy exposure will have a range of 50-100%. This chart is an essential tool for ensuring that the desired level of aggregate exposure is achieved on a polished concrete floor.

Grouting for aggregate

Grouting is commonly needed for full aggregate exposure floors. It affects the look of the floor by filling in the areas between the stones and giving the floor a more uniform and polished look. It can also provide a barrier for dirt and spills and can protect the floor from staining. The price of grouting will depend on the size of the area being grouted, the type of grout used, and the complexity of the job.

Holes and crazing of less than ⅜” are ideal candidates for the grouting material, but any holes or cracks larger than this should be treated with patching materials that are better suited for that application. It should be noted that if the concrete slab has a good density and consolidation of the fine aggregates, there will most likely be very little porosity or crazing, in which case grout would not be necessary.

Why choose Concreate?

At Concreate, we understand the importance of having the right team by your side to help manage polishing projects efficiently, professionally, and cost-effectively. Our experienced concrete contractors have the expertise and skills to complete the job correctly and on time. We are committed to providing quality, safety, and sustainability with our polishing services.

If you are looking for a reliable polishing contractor, please consider Concreate. We offer a free polishing project consultation and would be happy to discuss your project with you. To learn more about our services, project portfolio, and customer testimonials, please visit our website at thisisconcrete.com. We look forward to helping you with your polishing project.