How a Concrete Sealer Differs from a Concrete Densifier

The products have distinct purposes, but you can utilize them together for the ultimate floor protection

Key takeaways

- Densifiers and sealers are very different products

- A densifier fills the concrete’s pores and changes its composition

- Sealers create a protective layer over the floor

- You can use both products on the same floor for greater protection

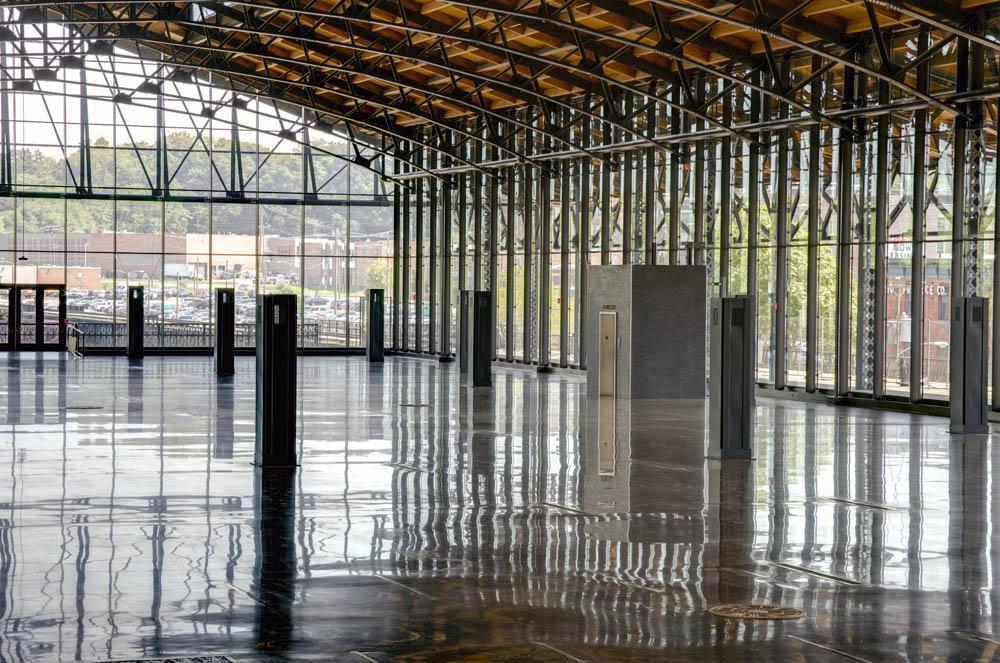

Concrete floors are an outstanding option for many projects because they’re long-lasting, low-maintenance, and attractive. This flooring will stand up to all kinds of abuse and withstand heavy traffic, although the treatments you add to the concrete influence its durability.

Two treatment options you should learn about are sealers and densifiers. These products will often come up in the same conversations, but they aren’t interchangeable. Learning about how these products differ helps you make the right decision for your project.

In short, a densifier creates a harder floor while a sealer protects the existing floor, but there is more to it. Here’s a look at the differences between a concrete densifier and a concrete sealer.

An overview of concrete sealers

A concrete sealer is a protective layer that covers your concrete and protects it from spills, dirt, grime, and weather. It can also reduce wear in high-traffic locations.

There are two common sealer types on the market – film-forming and penetrating. You’ll make your selection based on the job at hand and the location of your floor.

Film-forming sealers are a topical surface coating that creates a shielding layer over the floor. It adheres to the concrete’s pores, offering outstanding protection against moisture and spills. You can also quickly reapply sealants, ensuring your floor is always protected.

Multiple film-forming sealer types are also available, allowing you to choose one based on your budget and project. These coatings include acrylics, epoxies, and polyurethanes.

Acrylic sealers are UV resistant and create a thin film that protects against water and dirt. They come in different sheen levels, so you can select the option that looks best in your building. The main drawback is that they wear faster than epoxies or polyurethanes, so you’ll have to reapply the coating more often.

Epoxy sealers are more durable than acrylics and form a high-build shielding film over the concrete. This finish creates a long-lasting protective coating that’s abrasion-resistant and water-repellent. You can also choose a clear or pigmented finish, depending on your needs.

Polyurethane sealers are resistant to chemical spills and abrasions. This finish is thicker and more durable than acrylic options and works well on exterior applications. It’s also durable enough to apply in high-traffic areas. This sealer will enhance the beauty of your existing concrete since you can color or stamp the floor before application.

Penetrating sealers are best for outdoor applications because they do an outstanding job of protecting against the elements. They’re also breathable, allowing moisture to escape, and offer protection against corrosion and freeze-thaw damage.

A penetrating sealer doesn’t leave a film over the concrete, so it provides an invisible layer of protection. As a result, it’s often the best option when going for a natural-looking concrete floor.

Each sealer option helps protect your concrete floor, and the non-penetrative options offer a decorative effect. The sealer you select will ultimately depend on how you want your floor to look and the level of protection you require in your building.

What is a concrete densifier?

A concrete densifier is far different from a sealer because it improves durability by changing the concrete’s composition. A densifier fills in the pores at the concrete’s surface, increasing its density and making it more wear-resistant. The result is a harder floor that’s less prone to damage while offering some stain resistance.

A typical concrete floor slab is between four and six inches thick. However, most wear occurs on the top portion of the surface where people, furniture, and other items directly contact the material. A densifier is a liquid silicate concrete hardener that creates a chemical reaction in the concrete.

This reaction leads to a process called crystalline growth, which fills in the pores and makes the entire surface harder. It also locks up the concrete’s dust, so it won’t escape later as the surface wears down.

So, instead of protecting your concrete floor with a barrier, a densifier turns the material into a harder, more durable version of itself. The result is a low-maintenance floor that will stand the test of time.

When to use each product

The good news is that you don’t have to choose between concrete sealers and densifiers because the two products work together. Your contractor will probably use a densifier before polishing your concrete to tighten the floor up and improve its durability.

From there, you can opt for a concrete sealer application to provide even greater protection. The sealer is applied last, acting as a sacrificial surface that prevents stains from soaking into the concrete while preventing premature wear from foot traffic, furniture, or equipment.

Using these products together ensures you have the hardest concrete possible and an additional safeguard over the surface. The result is a floor with excellent stain and abrasion resistance. If you’re treating concrete floors in a commercial or industrial setting, using a densifier and sealer will minimize your maintenance requirements while creating a foundation that should stand the test of time.

Get the most from your concrete flooring

The goal when treating your concrete floors is to shield the material as much as possible. The better the concrete is protected, the less frequently the floors require maintenance and repair. Adding a densifier to the process makes the concrete more durable as well, delivering further protection.

You want your project to look great and perform at optimal levels, and Concreate can help. Our team can grind, densify, polish, stain, and seal your concrete floors, ensuring the result is a durable yet beautiful surface in your commercial or industrial building. Contact us or visit thisisconcrete.com for more information on concrete densifiers vs. sealers and how to use each product.